Product Technologies

Valve Manifolds

Flexibility and modularity have reached new levels with the Norgren VR Valve Manifold range.

View ProductsElectric Motion

Our range of high performance electric motion is suitable for a variety of industrial applications.

DiscoverPrecision Fluid Control

Our precision fluidic control solutions are designed and manufactured for the control, repeatability and safety needs of instrumentation OEMs.

DiscoverProcess Control Valves

An extensive range of process control including direct and indirect acting solenoids, pressure operated and motorized valves.

DiscoverHigh Pressure

Our products are capable of managing pressures up to 1000 bar and in safety critical applications in industries such as defense, nuclear and oil & gas.

DiscoverInnovation at Norgren

Active Control

Innovation to help Mass Flow Controller and Electronic Pressure Controller customers overcome issues including flow controlling range, modularity, and size.

DiscoverElectrolysis & Green Hydrogen

Our range of fluid and process control solutions, specifically designed to work with hydrogen at an industrial level, can take electrolyzer design to the next level – simply, safely and efficiently.

DiscoverConnecting the pneumatic circuit

IO-Link is revolutionizing automation by offering a standardized communication interface for all IO-Link devices, with simple installation and diagnostic functionality.

DiscoverWorkholding

We are challenging traditional thinking about workholding solutions for CNC machining customers. Powerfully grip the most challenging work pieces with innovative, reusable technology.

DiscoverWhat's new at Norgren

Norgren Minneapolis takes a significant step in reducing carbon emissions with a major new solar system

Discover how Norgren’s Minneapolis factory cut emissions and took a major step towards its climate goals with a large-scale new solar panel system.

How a 20-year partnership with Norgren took one company’s innovative product to new heights

Discover how Norgren helped a major multinational company design, manufacture, and deliver a crucial PPE product.

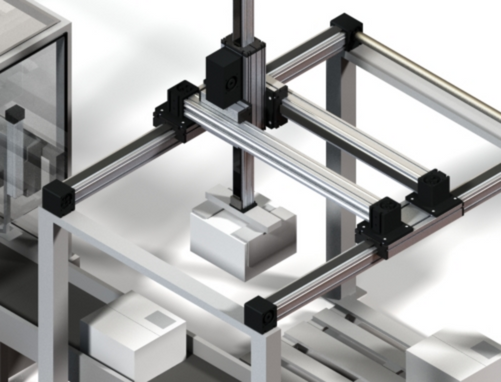

Key applications for Multi Axis Electric Motion Solutions

Linear and multi axis electric motion solutions* complement traditional pneumatic-driven options for the movement, placement, and positioning of components as part of an automated response.

Plan ahead to unearth Multi Axis Electric Motion benefits

Simon Gass from Norgren shares the critical considerations engineers should address when specifying multi axis electric motion control solutions*