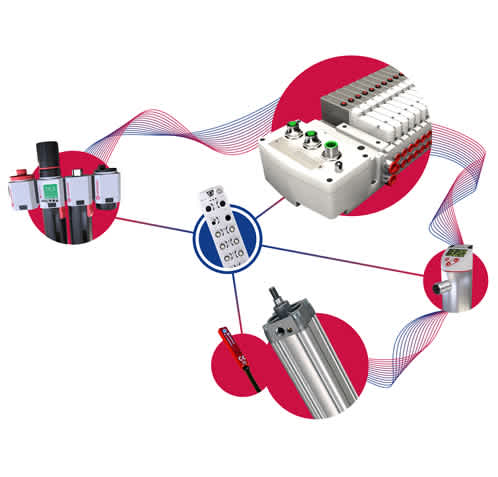

A complete IO-Link system. Designed and delivered by our experts.

In manufacturing, staying competitive means staying connected. And IO-Link is one of the most reliable, cost-effective, and efficient ways to connect your Industrial Internet of Things (IIoT) devices and take full advantage of Industry 4.0 and industrial automation. Ready to embrace IO-Link? We’ll provide you with a complete, connected IO-Link system solution, including a wide range of IO-Link-enabled devices, IO-Link masters, and I/O modules (hubs). With our expert support on your side, you’ll be able to maximise the impact of your connected systems.

More efficient

IO-Link technology automates and monitors the function of your pneumatic system, making it easy to find and fix inefficiencies.

More productive

Real-time monitoring of your pneumatic circuits gives you the data and diagnostics you need to make the best operational decisions.

Less downtime

Use data from your sensors to build predictive and planned maintenance schedules, or identify issues before they put a stop to production.

Excelon® Plus with integrated pressure sensor

The latest generation of air preparation equipment: compact, lightweight, robust, and designed to deliver exceptional results every time. Suitable for all industrial applications, our compressed air preparation solution takes the performance of your pneumatic ring main and equipment to new heights.

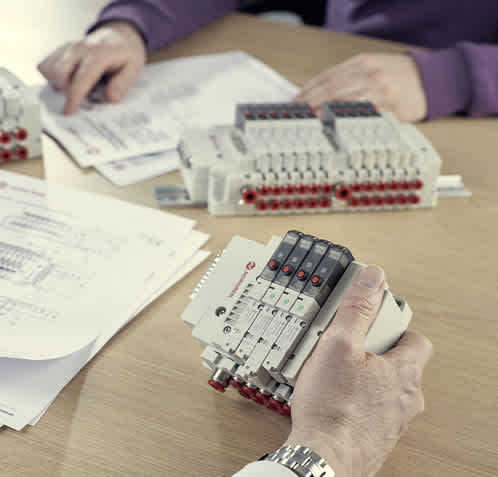

VR Series Valve Manifolds

Reach new levels of flexibility and modularity with a simple plug-in, sub-base style design that makes installation and maintenance simple. Effortlessly expand the size and functionality of your valve island to match your application’s changing needs – including the latest communication protocols like PROFINET, EtherNet/IP, EtherCAT, IO-Link Slave, and Multipole.

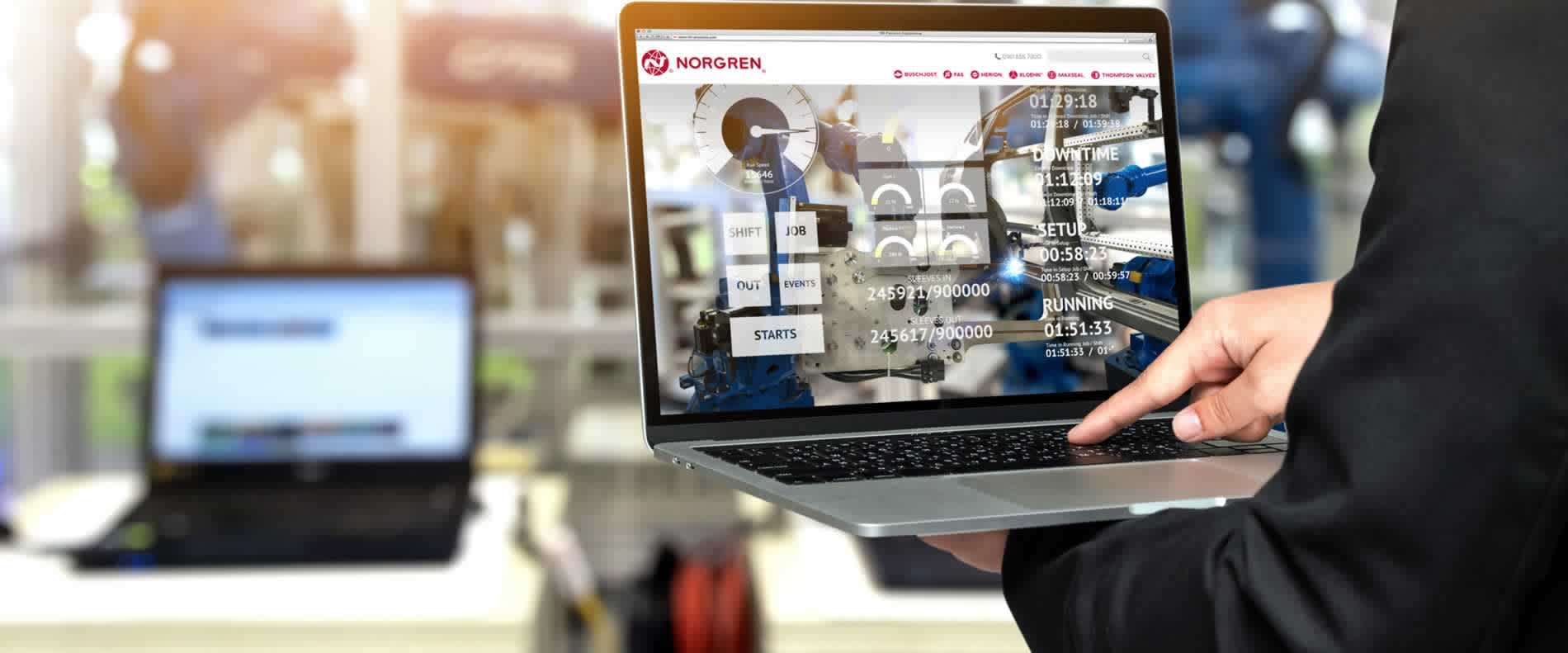

IO-Link masters & modules

IO-Link masters sit at the heart of your connected circuits. Seamlessly connecting your devices – sensors, valves, and input/output (IO) blocks for analogue devices – to an Ethernet system. IO-Link masters are your gateway to your machine data, process parameters, and diagnostic data. Giving you the information you need to take immediate action or run long-term analysis via an industrial information system like a PLC or HMI.

M/50 solid state switch

Our magnetically operated solid-state switch comes with standardized IO-Link capability – so it integrates easily with the rest of your IO-Link-enabled process chain. Our M/50/IOP switch delivers end-to-end communication and monitors temperature and operating modes, and comes with a built-in cycle counter.

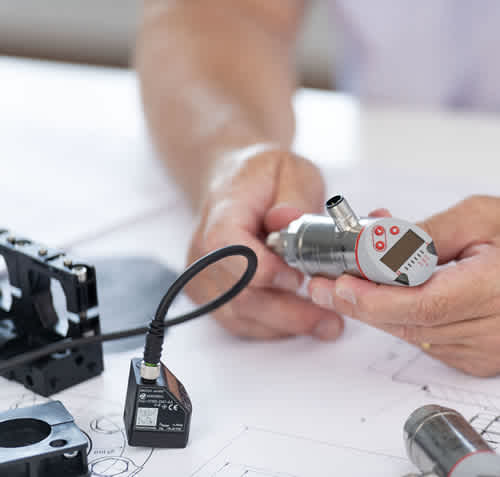

34D and 54D pressure sensors

Built for flexibility, accuracy, and long-term performance, our electronic pressure sensors help you react quickly and effectively to changing pressure requirements. Program pressure set points manually or remotely via IO-Link, and use digital displays and LED lights to keep a close eye on your operations. Electronic pressure sensors are particularly useful in applications where classic mechanical pressure switches are not suitable.