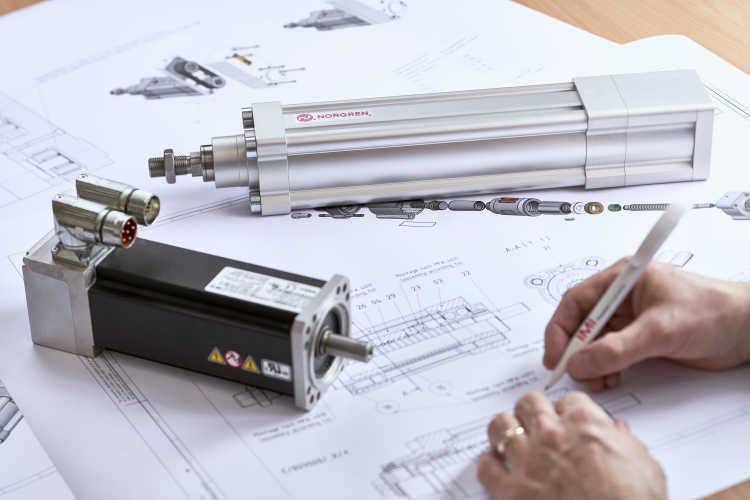

Our expanded range of high-performance electric motion solutions is suited to a variety of applications including material handling, pharmaceutical, food and beverage, battery manufacture and factory automation.

Our electric motion range includes electric cylinders, linear axis and custom-built cartesian and gantry systems for multi axis applications. The wide range of drive, guide and profile options, with over 100,000,000 possible configurations, allows us to design and manufacture solutions that offer complete flexibility. From improving the speed, productivity, and reliability of equipment, to generating significant energy and efficiency savings, or lowering the total cost of ownership, our electric motion solutions deliver Breakthrough Engineering you can count on.

30+ years experience

Our Electric Motion products are built on over 30 years of extensive application experience, to deliver Breakthrough Engineering you can count on.

Application engineering

We offer an unparalleled engineering service including Application Engineering support, complete 3D CAD models & drawings, and life & cycle time calculations.

Service and support

To ensure we meet your exact specifications and to guide you in choosing the right solution for your application, our experienced technical team provide comprehensive needs assessment, advice, and technical support from design through to delivery.

Electric motion applications

We offer customized solutions to suit every automation application. From a single, individual cylinder or repeat, high volume production runs, we offer the best motion control technology for your specific application.

Mechanical and systems engineering

Coating, painting, welding, measuring and forming plants; glass, stone and woodworking machinery

Automation and electrical engineering

Assembly lines and storage systems, assembly and handling systems, and measuring and inspection equipment

Lifting and materials handling technology

Bottling and dosing systems, electro-mechanical lifting systems, lift systems, and pick and place systems

Food industry

Food production and animal feed production

Chemical and pharmaceutical industry

Mixing, testing and dosing equipment, laboratory applications and clean-room conditions

Pharmacy automation

Automated picking systems

Packaging technology

Labelling and packaging equipment, and systems for cartoning, loading, packaging and delivery

3D Printing

Rapid prototyping, industrial 3D printing, sintered metal processing and architectural projects

Commitment to engineering and service

Our electric motion solutions are designed by engineers, to the most demanding standards. To ensure you make the right decision, our dedicated technical team is available to help you specify the best product for your application, and provide full technical support throughout purchase and delivery.

Webinars: Engage, learn, and transform your approach to electric motion

In these on-demand Webinars, our electric motion product specialists provide you with technical insights and practical advice to enhance your understanding of the fundamentals of electric motion and explore how it can transform your operations.