Precision single linear axis units offer unique flexibility due to their modular construction from the highest quality profile, guide, drive, and accessory building blocks.

Each linear axis can be individually configured and modified, and in addition to our standard units, we also offer stainless steel and reinforced components suitable for applications in explosion protection (ATEX), food processing and clean room areas. We also offer a wide range of accessories such as motors, drives, connection shafts, switches, gearbox reducers, safety brakes, cable chains and more which allow us to customise our linear axis to your individual needs.Linear axis with tooth belt drive

Linear axis with tooth belt drives can be found in every industry and in a variety of applications. No matter how often and how far you want to move your workpieces, belt-driven linear units are ideal for fast handling and positioning tasks. The linear axis is driven by a steel-reinforced tooth belt moving lightweight or heavy loads from point A to B within the desired cycle time. Characterised by high speeds, they deliver impressive results even over long travel distances. The positioning of the carriage is achieved by means of a roller guide or rail guide, depending on the product series and the application requirements.

Linear axis with spindle drive

Linear axis with spindle drives can generate high feed forces and offer extremely precise positioning accuracy and repeatability - making them a popular standard in processing, dosing and positioning applications. Our spindle drives are characterised by excellent accuracy, guaranteed even under harsh operating conditions and with long operating times. The systems are driven either by a trapezoidal threaded spindle or by a ball screw spindle. For positioning the carriage, you can choose between a sliding guide, roller guide or rail guide.

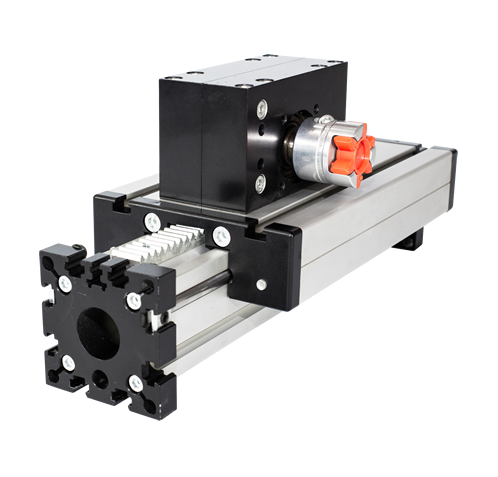

Linear axis with rack and pinion drive

Linear axis with rack and pinion drives are ideally suited for applications where extremely heavy loads need to be moved over long distances. Even with heavy loads, they provide the most precise positioning accuracy. Additionally, this design allows for several carriages to be operated independently of each other on the linear unit. Rack and pinion systems are ideal for lifting heavy loads and for use in cartesian systems. The positioning of the carriage is achieved using a roller guide or rail guide, depending on the product series and the application requirements.