Effective, efficient, and safe.

Delivering a safe, efficient, reliable, and sustainable rail service isn’t easy, but we’ll be your partner every step of the way. With more than four decades of in-depth rail experience, we’ll provide you with pneumatic control solutions tailored to your precise needs. So that you can keep business, goods, and people moving on the railways, no matter what happens.

Years of global rail expertise

Countries with local sales & service

Products designed for -40°C to +80°C

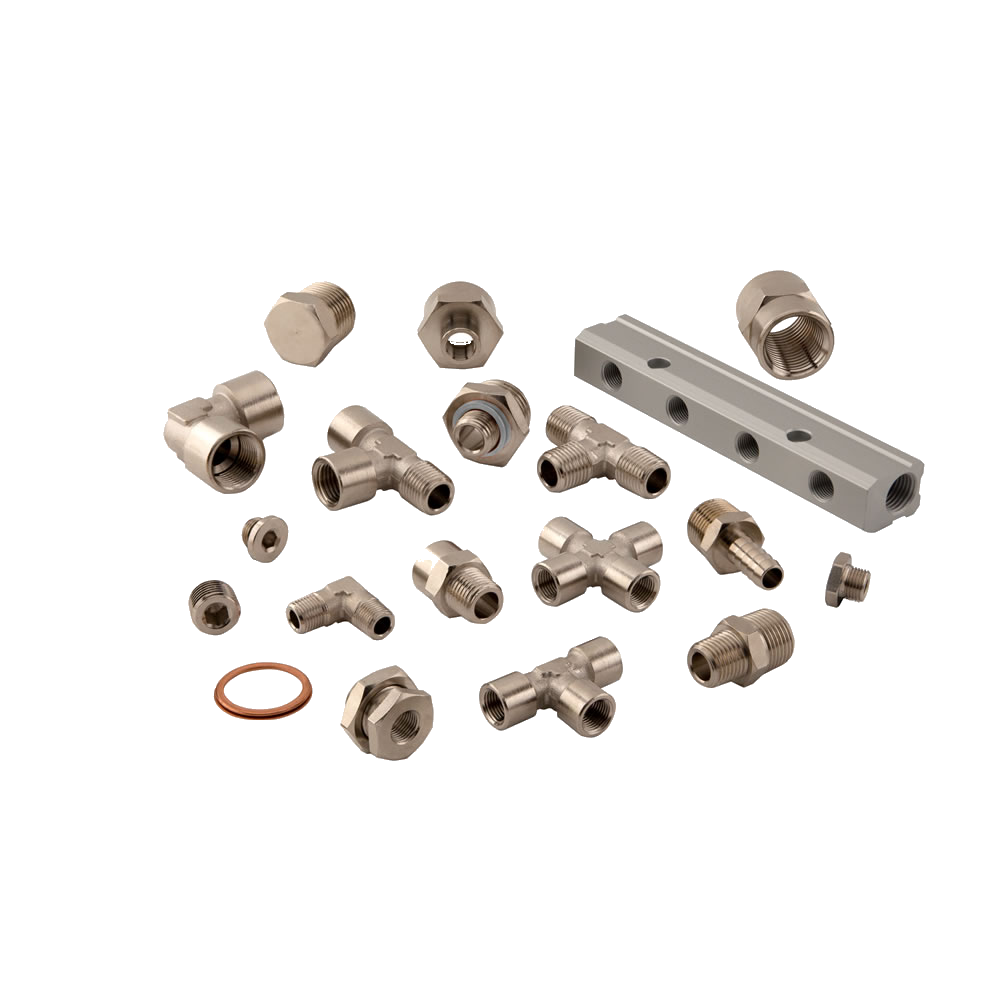

Innovative, Reliable, and Built to Last

Beyond these key applications, our expertise extends to critical rail systems such as water management, air preparation, couplings and nose cones, freight systems, and sanding control. From high-performance solenoid valves for water systems to robust air filtration equipment, customised manifold solutions for couplings, and modular control systems for sanding, each product is designed to meet the highest standards of safety, reliability, and efficiency. With over 45 years of experience, we deliver solutions that ensure seamless operation, even in the harshest environments, keeping rail networks moving forward with confidence.

Need the perfect solution? We’ll work together to help you reach your goals.

We work closely with maintenance professionals and rail engineers to deliver practical, custom solutions to the metro, intercity, high-speed, freight, and permanent-way rail industries. By listening and responding to specific customer challenges, we help make significant improvements and savings – so you can save money, reduce maintenance, and drive energy efficiency.