Technologie produktów

Przygotowanie powietrza

Filtry, regulatory ciśnienia, smarownice i inne elementy związane z przygotowaniem powietrza.

OdkryjNapędy Elektryczne

Szeroka oferta napędów elektrycznych zapewniających wysoką precyzję i wydajność, odpowiednich dla większości aplikacji przemysłowych.

ODKRYJZawory procesowe

Zawory sterujące przepływem lub zawory procesowe regulują przepływ powietrza, gazów lub cieczy w różnych zastosowaniach przemysłowych.

OdkryjInnowacje

Wyspy zaworowe serii VR

Elastyczność i modułowość osiągnęły nowy poziom dzięki wyspom zaworowym VR.

OdkryjSystemy wieloosiowe

Systemy wieloosiowe i systemy suwnic bramowych są projektowane na zamówienie pod kątem konkretnych wyzwań i zastosowań.

OdkryjPołączone obwody

Standard IO-Link rewolucjonizuje automatykę przemysłową, ponieważ umożliwia stosowanie znormalizowanego i płynnego interfejsu komunikacyjnego dla wszystkich urządzeń z IO-Link, który upraszcza montaż i funkcje diagnostyki.

ODKRYJOdkryj

Powitanie Daniela Coetzee jako lidera rozwoju automatyki przemysłowej

Z przyjemnością witamy Daniela Coetzee na stanowisku wiceprezesa ds. rozwoju naszego działu automatyki przemysłowej. Dzięki ponad 25-letniemu doświadczeniu na wyższych stanowiskach kierowniczych, Daniel wnosi ogromną wiedzę, która pomoże nam wprowadzać innowacje i zapewniać lepsze wsparcie dla naszych klientów w wielu różnych branżach.

Zwiększanie wydajności i bezpieczeństwa w górnictwie dzięki rozwiązaniom automatyki przemysłowej

Wydajność, bezpieczeństwo i zrównoważony rozwój mają kluczowe znaczenie w górnictwie. W całym regionie APAC automatyka przemysłowa rewolucjonizuje operacje, pomagając firmom radzić sobie z wyzwaniami i spełniać wymogi regulacyjne.

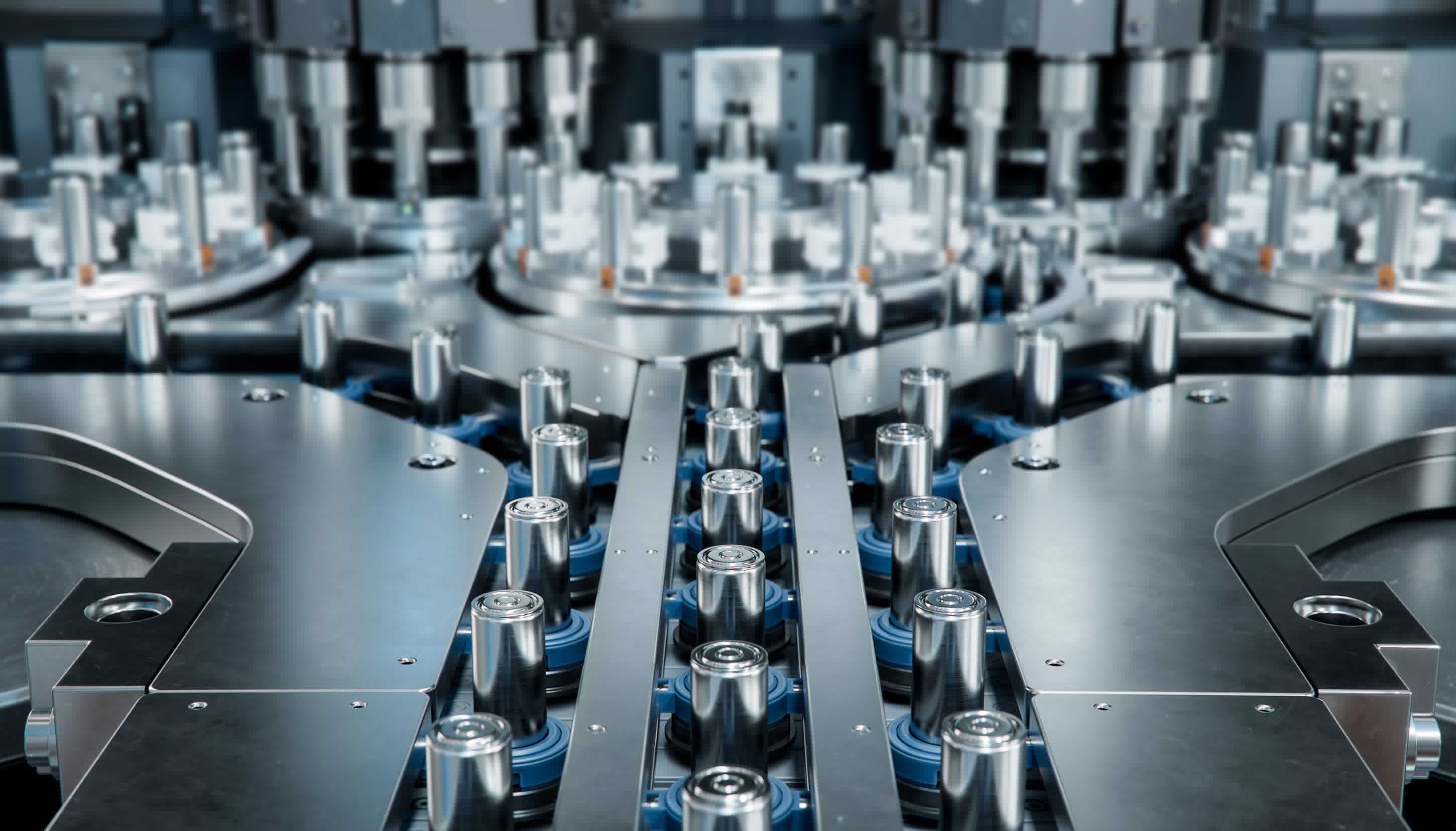

Rewolucja w zaworach dozujących napoje: Odpowiedź na wyzwanie związane z osadzaniem się kamienia

W przemyśle spożywczym precyzja i niezawodność są podstawą jakości. Jesteśmy dumni, że możemy zaoferować pakiet rozwiązań do kontroli płynów, które nie tylko sprostają tym wyzwaniom, ale także na nowo zdefiniują standardy dozowania napojów.

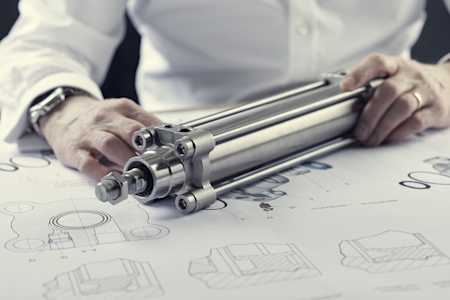

Optymalizacja zużycia sprężonego powietrza w dużym centrum dystrybucyjnym

Dowiedz się, w jaki sposób międzynarodowy producent silników zmniejszył zużycie sprężonego powietrza o 10% w swoim centrum dystrybucyjnym w Amsterdamie dzięki butli IMI Norgren IVAC.