With a well-established presence, we offer high-quality, reliable solutions to meet the strict standards and regulations of the biopharma industry.

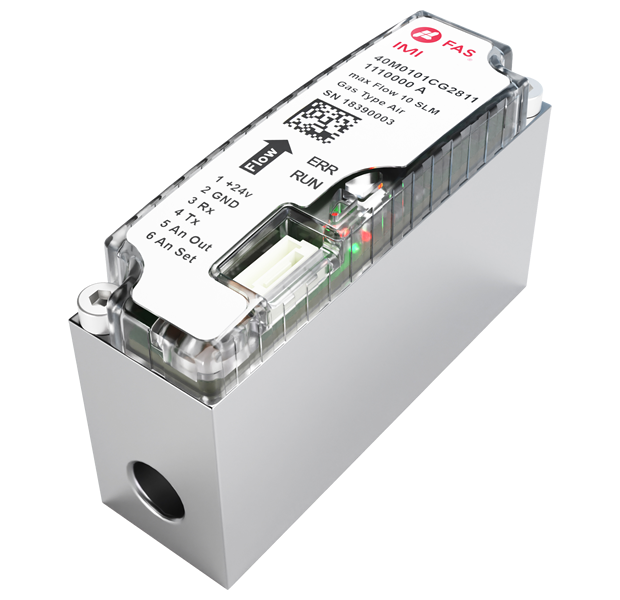

We offer a range of valves, regulators, mass flow controllers (MFC), fittings, tubing, and other fluid control components specifically designed to meet the needs of bioprocessing applications, such as USP Class VI and FDA-approved materials, easy sterilisation, and accurate control of flow rate.

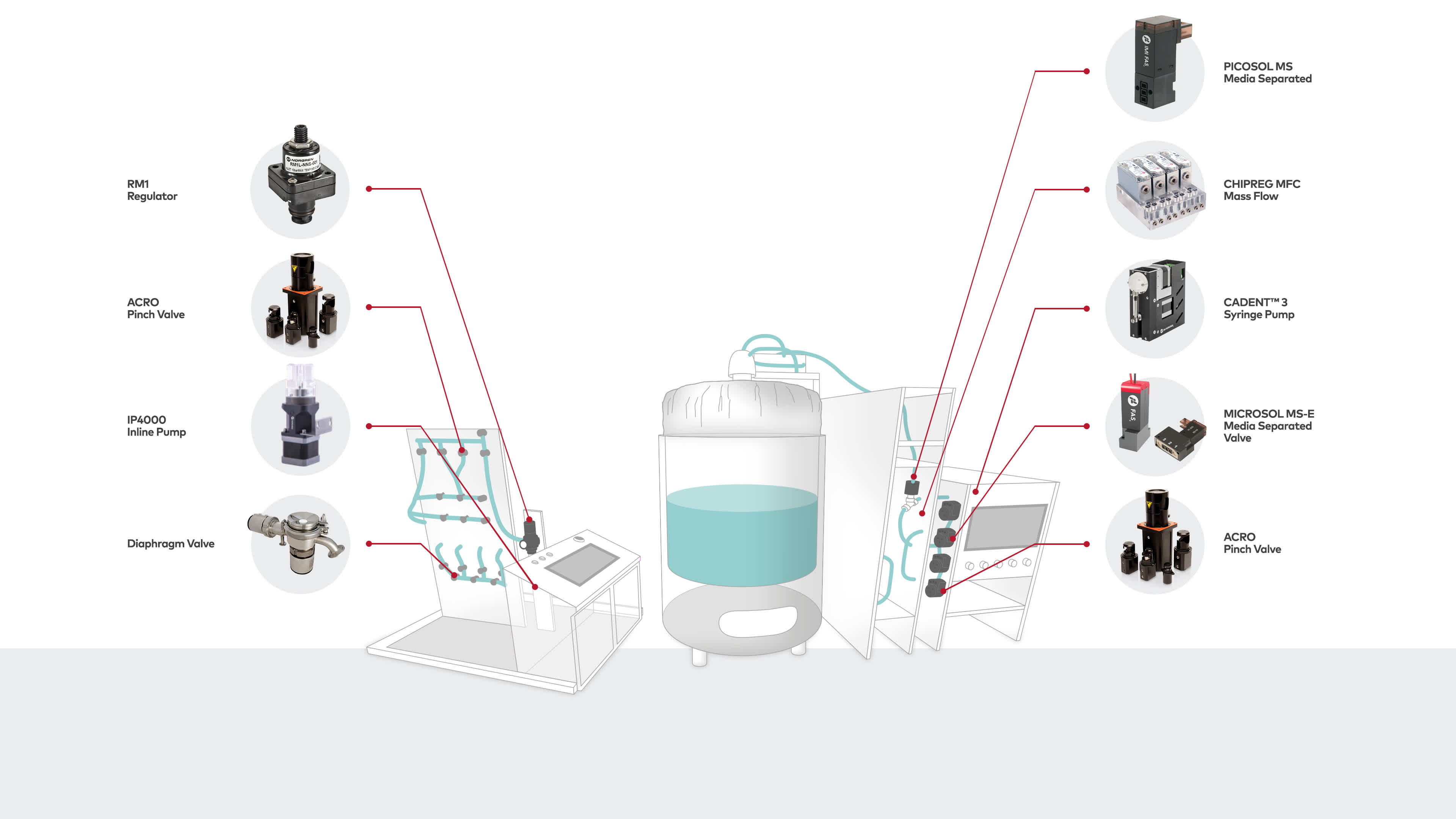

Bioreactors

Bioreactor setup requires careful planning and execution. It involves several critical components and parameters that must be carefully controlled and monitored.

A multidisciplinary approach, involving experts in bioprocessing, engineering, and regulatory compliance is required for a successful outcome.

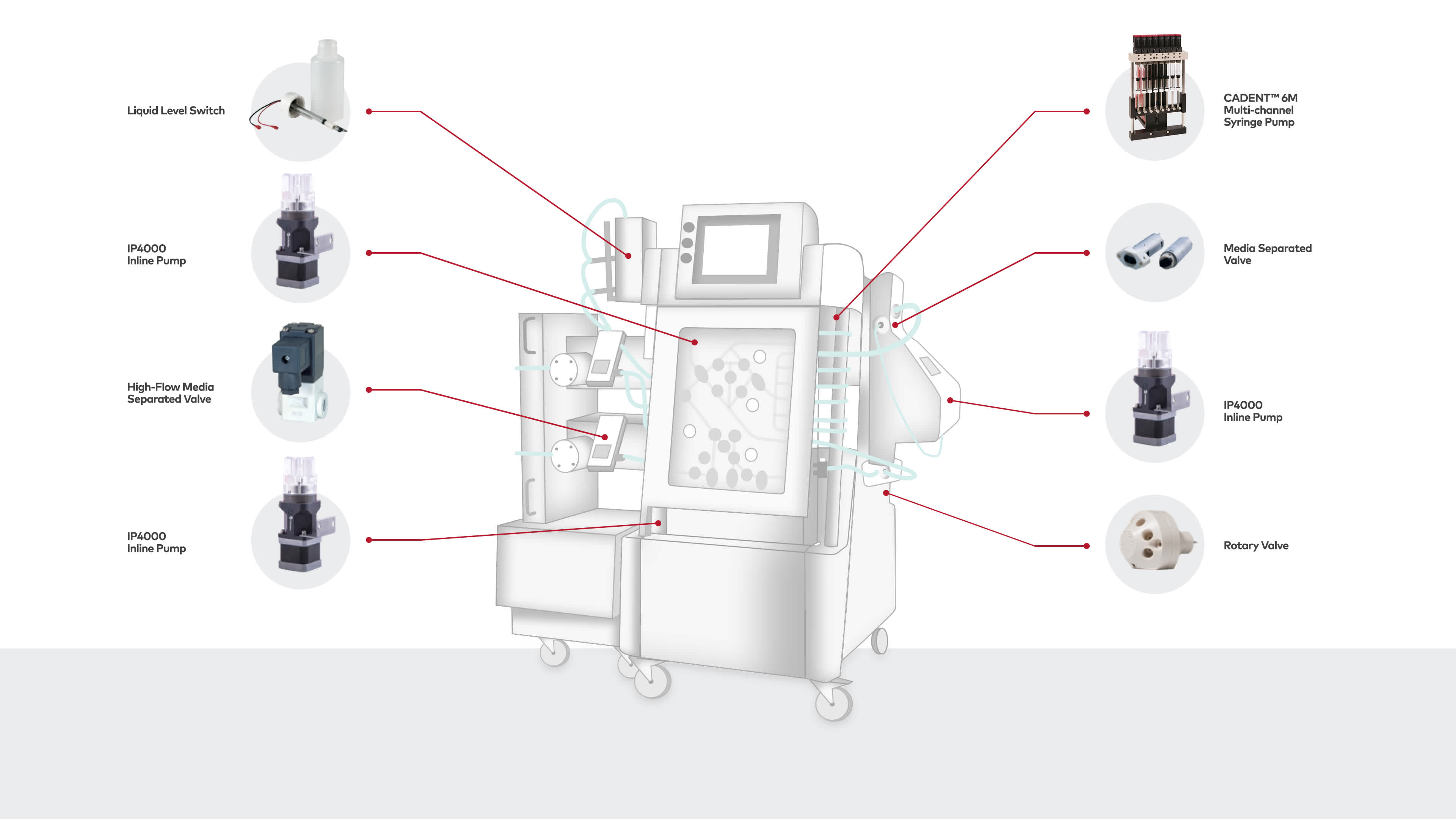

Flow Filtration / TFF / CFF

Tangential flow filtration (TFF) is a membrane-based separation technique used in bioprocessing to separate and purify biomolecules based on size, charge, and other properties.

TFF is used for the concentration, desalting, fractionation, and clarification of samples. It requires careful optimisation of membrane pore size, flow rate, and pressure to achieve the desired separation and purification efficiency.

Norgren pinch valves are used in TFF systems to control the flow of liquid in the retentate and permeate streams, allowing for accurate and efficient adjustment of the flow rate, without causing shear stress or clogging the membrane. A reliable and efficient way to control the flow rate in TFF systems, they are widely used in bioprocessing applications due to their high accuracy, low maintenance, and ease of use.

Norgren pinch valves are a reliable choice for many bioprocessing applications that require accurate and gentle flow control. As with any equipment, it's important to consult with our technical experts to ensure that the specific pinch valve is suitable for the intended bioprocessing application.

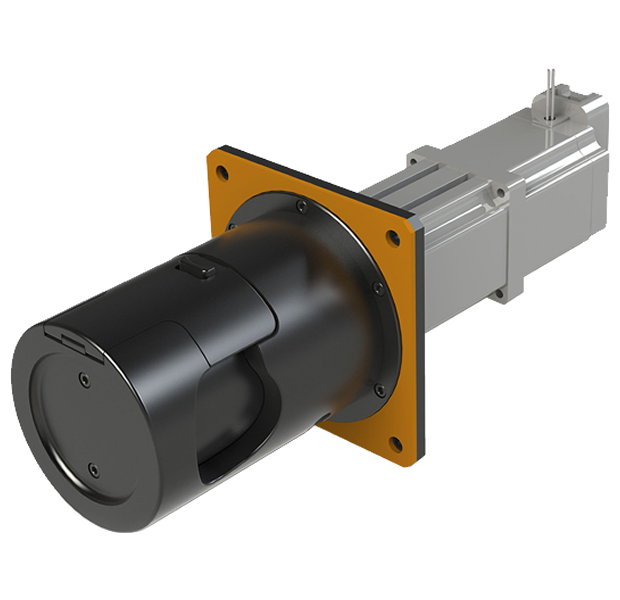

Chromatography

Chromatography is a technique commonly used in bioprocessing for the purification of biopharmaceuticals, such as proteins, antibodies, and other biologics.

The goal of chromatography in bioprocessing is to separate and purify the target molecule from a complex mixture of other proteins and impurities, often produced by biological sources such as cell cultures.

The principle of chromatography is based on the differential binding of the target molecule and impurities to a stationary phase, typically a resin packed into a column. The mixture is passed through the column, and the target molecule is selectively bound to the stationary phase, while impurities pass through or are eluted later from the column. The target molecule is then eluted from the column using a buffer solution that alters the binding properties of the stationary phase.

Chromatography can be used in different modes, depending on the type of interaction between the stationary phase and the target molecule.

Chromatography is a critical step in bioprocessing because it enables the purification of the target molecule to high levels of purity, which is required for regulatory compliance and safety in biopharmaceutical manufacturing.

Fill and finish

Fill and finish is the final step in bioprocessing, where the purified drug substance is formulated, sterilised, filled into the final container, labelled, and packaged for distribution.

It is a critical step that requires strict quality control and regulatory oversight to ensure the product's safety, efficacy, and stability.

Norgren offers a range of products for fill and finish systems, including pinch valves, proportional pinch valves, pressure regulators, filter regulators, air preparation units, and a variety of fittings and tubing.

Pinch valves are commonly used in fill and finish systems due to their ability to precisely control the flow of liquids without contaminating the product or affecting its quality. Proportional pinch valves are also used for precise flow control and are designed to meet the high sanitary requirements of the pharmaceutical industry.

Norgren's pressure regulators are designed to accurately control the pressure of gases and liquids in the system, ensuring consistent product quality and avoiding overpressure that could damage the product or equipment.

Norgren's range for fill and finish systems is designed to meet the high standards of the pharmaceutical industry, ensuring reliable and efficient operation while maintaining product quality and safety.

“Your fully integrated gas control manifold enabled us to reduce size by a factor of three, reduce costs 50%, increase reliability through reduction of tubing and connectors, and work with a single supplier instead of five.”

Director of Engineering | Benchtop Bioreactor