Product Technologies

Air Preparation

Filters, pressure regulators, lubricators and more air preparation components.

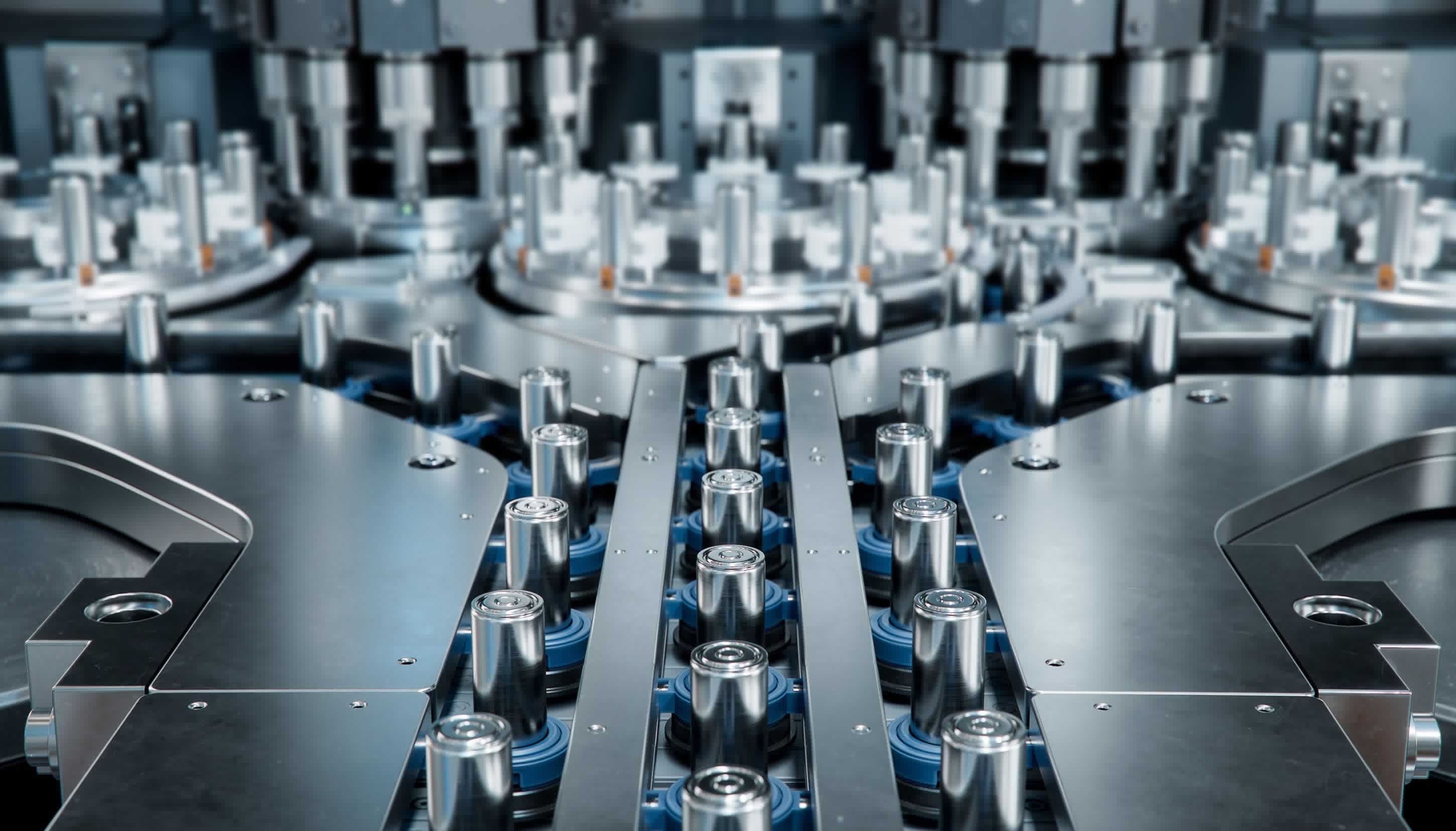

DiscoverElectric Motion

Our range of high performance electric motion is suitable for a variety of industrial applications.

DiscoverFluid Control Valves

Fluid Control Valves, or Process Valves, regulate the flow of air, gases, or liquids across various industrial applications.

DiscoverInnovation

VR Valve Islands

Flexibility and modularity have reached new levels with the IMI Norgren VR Valve Island range.

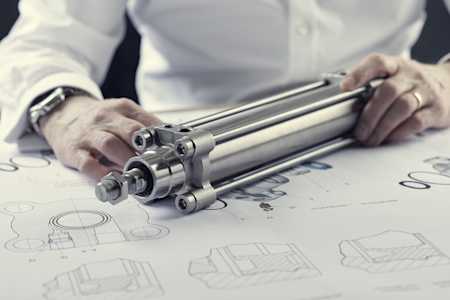

DiscoverMulti Axis Systems

Multi axis and gantry systems are custom designed to solve specific application challenges.

DiscoverConnected Circuits

IO-Link is revolutionising industrial automation by offering a standardised and seamless communication interface for all IO-Link devices, with simple installation and a complete range of diagnostics functionality.

DiscoverDiscover

Prevention is better than cure for optimising your systems’ performance

Optimise your production performance, increase efficiency, and unlock significant savings with these key preventative maintenance insights for manufacturers.

Welcoming Daniel Coetzee to Lead Growth in Industrial Automation

We are pleased to welcome Daniel Coetzee as Vice President of Growth for our Industrial Automation division. With more than 25 years of experience in senior leadership roles, Daniel brings vast expertise to help us drive innovation and deliver enhanced support for you, our customers, across a wide range of industries.

Powering Efficiency and Safety in Mining with Industrial Automation Solutions

Efficiency, safety, and sustainability are critical in mining. Across the APAC region, industrial automation is revolutionising operations, helping companies tackle challenges and meet regulatory demands.

Showcasing custom Industrial Automation solutions at SPS Italia 2025

The future of industrial automation is taking centre stage at SPS Italia 2025, and visitors are invited to join IMI’s Industrial Automation team from May 13th to 15th at Fiere di Parma, Parma.