Product Technologies

Air Preparation

Filters, pressure regulators, lubricators and more air preparation components.

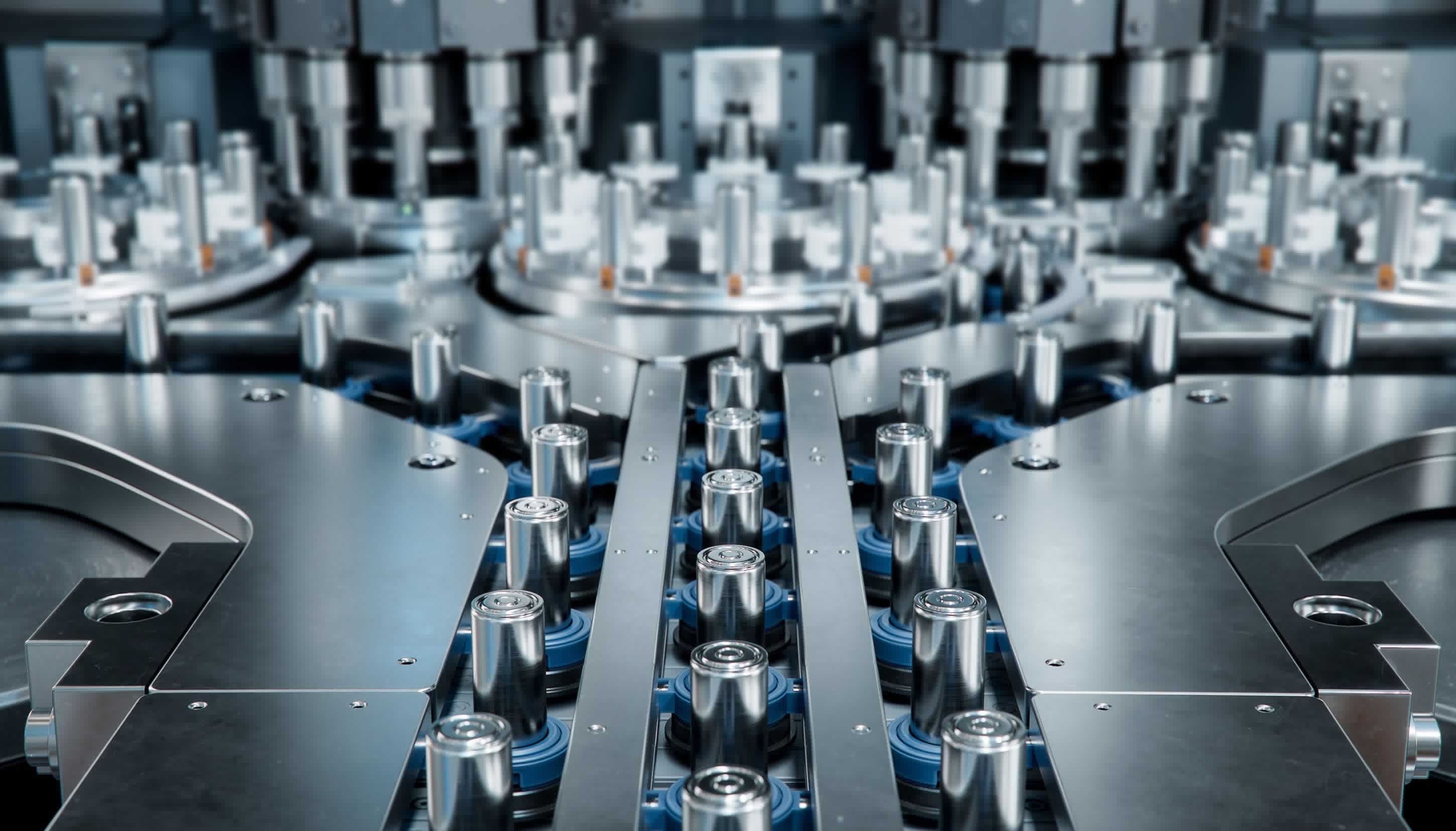

DiscoverElectric Motion

Our range of high performance electric motion is suitable for a variety of industrial applications.

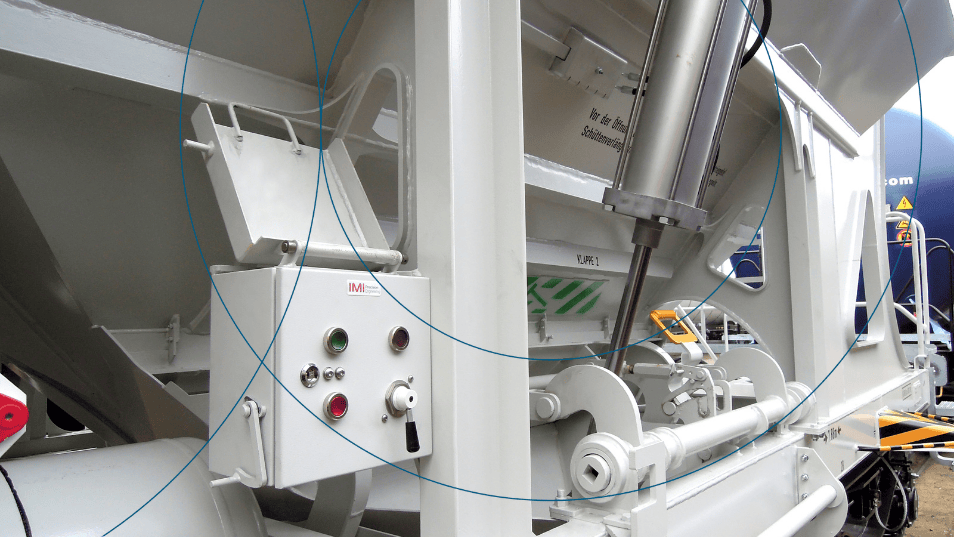

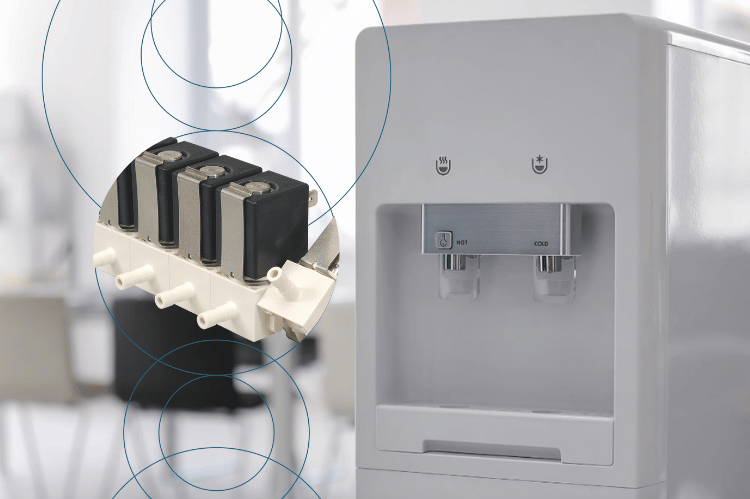

DiscoverFluid Control Valves

Fluid Control Valves, or Process Valves, regulate the flow of air, gases, or liquids across various industrial applications.

DiscoverInnovation

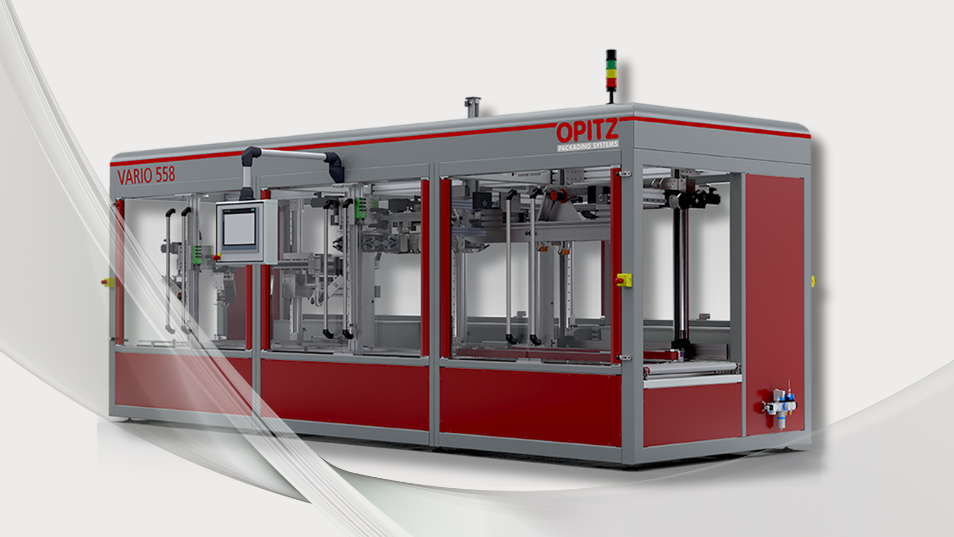

VR Valve Islands

Flexibility and modularity have reached new levels with the IMI Norgren VR Valve Island range.

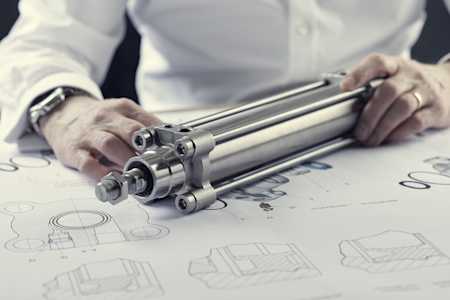

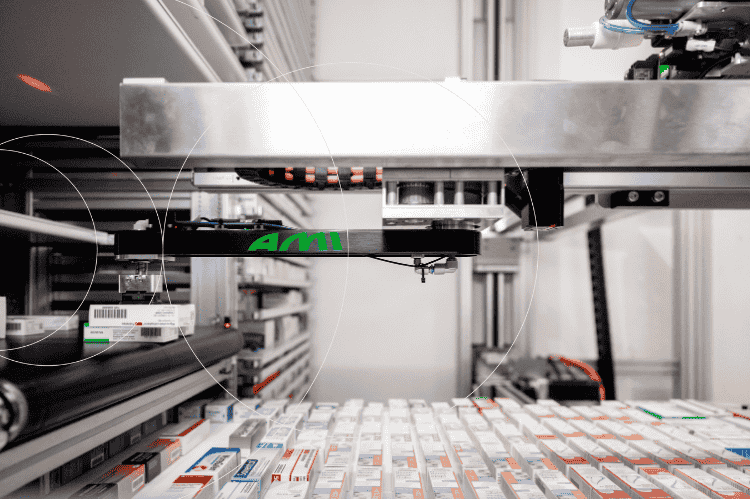

DiscoverMulti Axis Systems

Multi axis and gantry systems are custom designed to solve specific application challenges.

DiscoverConnected Circuits

IO-Link is revolutionising industrial automation by offering a standardised and seamless communication interface for all IO-Link devices, with simple installation and a complete range of diagnostics functionality.

Discover